MONITORS MOVEMENT OF DIVIDER

VALVE PISTON FOR DEPENDABLE

"TIMED" SHUTDOWN PROTECTION

OPEN and CLOSED LOOP OPERATION

INSTALLS DIRECTLY TO DIVIDER VALVE

NOT AFFECTED BY TEMPERATURE OR OIL

VISCOSITY

REQUIRES NO EXTERNAL POWER

FIELD REPLACEABLE BATTERY

LCD DISPLAYS:

TOTAL DIVIDER VALVE CYCLES

AC OR DC OPERATION

SPECIFICATIONS

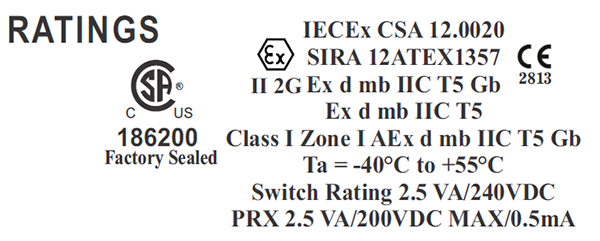

Temperature Range.............................................. -40C to +55C

Switch RaTing...................................................2.5VA/240 VDC

Epoxy Encapsulated.......................UL LISTED EL-CAST VFR 641

Power............................................Field Replaceable - Lithium Battery

............................................3.6 Volt, 1.5Ah, 75mA MAX Contentious Current

Alarm/Shutdown..................................000149 - 45sec Alarm Time

...........................................................000353 - 2 Min Alarm Time

...........................................................000150 - 3 Min Alarm Time

..........................................................000360 - 4Min15sec Alarm Time

Battery........................................................................ P/N 000505

Divider Block Application............SBCO/Lincoln/Dropsa

Warranty.........................................................................2.5 Years

RATINGS

DESCRIPTION

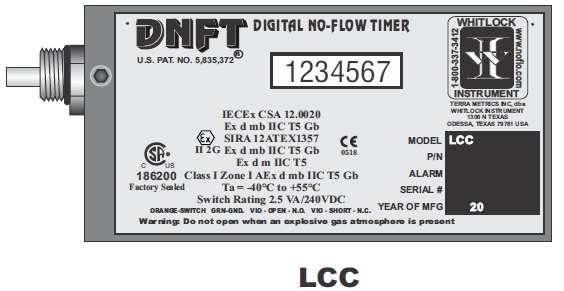

The DNFT-LCC is a totally enclosed electronic device, combining the latest

technology in microprocessor and transistor components for detecting Slow-

Flow and No-Flow of divider block lubrication systems. The DNFT

incorporates an oscillating crystal to accurately monitor the cycle time of the

lubrication system to enable precisely timed shutdown capability. The

magnet assembly and control housing mount directly to the divider valve to

become an integral part of the lubrication system. The DNFT-LCC operates

on field replaceable lithium battery. If battery voltage drops below normal

operating levels, the DNFT goes into alarm mode and the unit cannot be

restarted. The LCC comes with a liquid crystal display to display to divider

valve cycle and total divider valve cycles. The DNFT has been designed and

rated for use in Class I Zone I environments, to be used in wet or dry locations, in

altitudes under 2000 meters, with a Pollution Degree of 4.

OPERATION

Lubricant flow through the divider valve assembly forces the pistons to cycle

back and forth causing a lateral movement of a magnet linked to the piston.

Movement is monitored by the microprocessor which resets the timer and

allows the unit to continue operation. This indicates one complete cycle of the

lubrication system. The microprocessor must receive this cycle in a

predetermined time or a shutdown will occur. The DNFT will automatically

reset alarm circuit when normal operation of divider valve resumes.