< Back to Lubrication Monitors

Digital Lubrication Monitor Model DLM-926PM - Part# 000551

DUAL ZONE MONITOR (COMPRESSOR/ENGINE)

MONITORS AND RECORDS OPERATION OF DIVIDER BLOCK LUBRICATION SYSTEMS

SYSTEM SCAN MODE: Each 10 seconds

the readout will switch between the

following:

Compressor and Engine Pints per Day

COM. 24.1 P/D

ENG. 32.8 P/D

Compressor running seconds and

previous cycle time

COM. 23.1 sec.

PREV. 45.6 sec.

Engine r unning seconds and previous

cycle time

ENG. 23.1 sec

PREV. 36.8 sec.

Compressor and Engine total strokes

COM. 000231 STRKS

ENG. 000456 STRKS

System total r un time in hours

RUNTIME.

000000.000

SPECIFICATIONS

Enclosure.... ................ CLASS I, DIV I GROUPS C, D; T4

Panel mount in 4.5” Pressure Gauge hole

Power.....................................................................6-24VDC@.0007 amps

(Optional 90-200 Ignition or 120 VAC @.0005 amps)

Alarm Switch ............................................240 VDC or 120 VAC @ 2.5VA

Alarm Time......................................Programmable - 3 sec to 250

seconds

Temperature Range......................................................... -40O to +80O C)

Warranty............................................................................................1 Year

Display................Cycle Time(Sec), Flow Rate(Pints/Day), Total Strokes,

Alarm Status, Total System Run Time(Hours)

Memory..................100 Cycle times Compressor, 100 Cycle times

DESCRIPTION

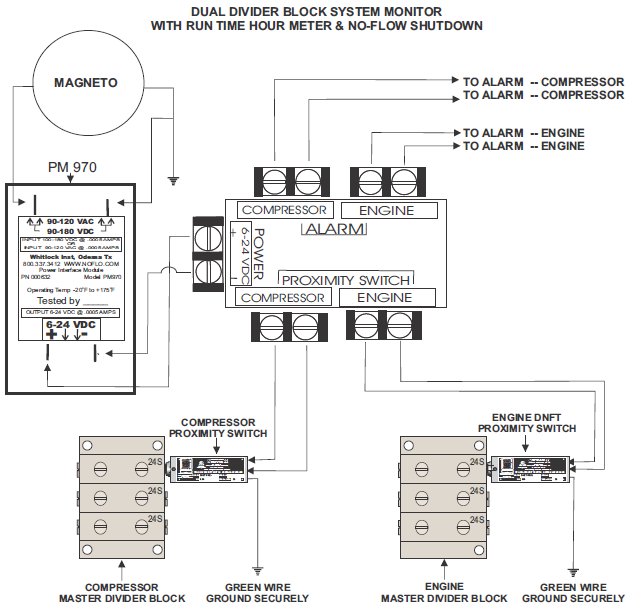

The DLM-926 is a microprocessor based dual mode

monitor for the display and control of progressive in- line

lubrication systems. Proximity switches mounted to the

divider block system on the engine and compressor

signals the DLM-926 each cycle. The time between

cycles is displayed on the LCD readout as time into the

current cycle as well as the time for the previous cycle.

Each 10 seconds the display changes to show the flow

rate in pints/day, cycle time, total strokes, and system

run time for both the engine and compressor. If the time

between cycles exceeds the programed alarm time an

alarm signal is activated. The DLM-926 alarm function

can be either open or closed loop depending on the

program setting. The last I 00 cycle times for the engine

and compressor lubrication systems are stored in

permanent memory and can be read out via local control

of program buttons. The DLM-926 is powered by 6-24

volts DC with an optional module PM970 (PN000632) to

ENCLOSURE NOTES

-OPEN CIRCUIT BEFORE REMOVING COVER

-OUVRIR LE CIRCUIT AVANT D’ ENELEVER LE COUVERCLE

-KEEP COVER TIGHT WHILE CIRCUITS ARE LIVE

-GARDER LE COUVERCLE BIEN FERME TANT QUE LES SONT SOUS TENSION

-SEAL SHALL BE INSTALLED WITHIN 50MM OF THE ENCLOSURE

-UNSCELLEMENT DOIT ETRE INSTALLE A MOINS DE 50MM DU BOITER

PROGRAMMING FUNCTIONS

Press Mode then Mode and UP or Down buttons to change

functions.

Pressing Exit button will return to normal scan.

1> Compressor Block Total - Can be changed in the range of variable

18-144 (Change with UP or DOWN Button) Total of the face

value stamped on the divider sections..

2> Engine Block Total - Range of variable 18-144 (Change with UP or

DOWN Button)

NOTE: For block totals see Sizing Chart for Dropsa.

3> Compressor Alarm Time - Range of variable 3-250 seconds(Change

with UP or DOWN Button)

4> Engine Alarm Time - Range of variable 3-250 seconds(Change with

UP or Down Button)

5> Alarm mode - (Change to Open loop with Down Button or Closed loop

with UP Button)

6> Compressor Cycle Time Memory - Last 100 cycle times given in

seconds(Sequence with UP or DOWN Button).

7> Engine Cycle Time Memory - Last 100 cycle times given in

seconds(Sequence with UP or DOWN Button).

NOTE: Memory is permanent, will not be lost in case of power failure.

8> System Reset - Press the up and down buttons at the same time to

Reset total strokes and total run time.

Four(4) panel mounted buttons are used to change the setup

parameters.

Program menu items are accessed by pressing the mode button.

Pressing the mode and either up or down at the same time will access the

other menu items.

The up and down buttons will change a menu item slowly at first then rapidly

if held down.

The exit button will return to the display mode if pressed at any time.

< Back to Lubrication Monitors