< Back to Lubrication Monitors

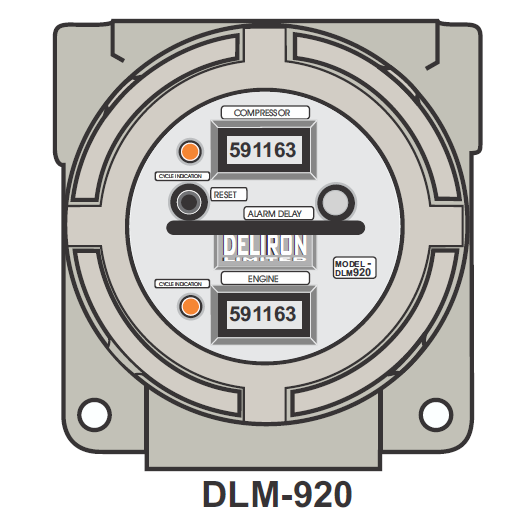

Digital Lubrication Monitor Model DLM-920 - Part# 000190

MONITORS AND RECORDS OPERATION OF DIVIDER BLOCK LUBRICATION SYSTEMS

FAILSAFE-OPEN AND CLOSED MODES

STANDARD DIGITAL READOUT

EXTERNAL POWER: NOT REQUIRED

EXPLOSION PROOF

TIMED SHUTDOWN PROTECTION

PROGRAMMABLE ALARM TIME

DC POWERED

The DLM-920 operates with two (2) "AA"

regular or alkaline batteries which are

easily replaceable. The low-cost batteries

have a life expectancy of between 5 and

10 years depending on the cycle time of

the divider block. The DLM-920 comes

equipped with a "Low Battery Function".

The Cycle Indicator light is the “Low

Battery” light. After thirty (30) days of

flashing the low battery warning, the DLM-

920 will go into alarm state and cannot be

reset until batteries have been replaced.

SPECIFICATIONS

Material........................................................................Aluminum

Temperature Range. .................................................-40 F to +170F

Alarm/Shutdown.........................................Programmable - 20 sec to 4 min 30 sec Alarm

Power...........................................................................2 “AA” 1.5V Batteries

Switch Rating............................................................ 2.5VA/120VAC/240 VDC

Warranty.....................................................................2 Years

Display/Strokes.........................................................0-99999

ENCLOSURE RATINGS

FM Approved Instr Housing:

CLASS I, GROUPS B, C, D

CLASS II GROUPS E, F, G

CLASIII TYPE 4X

DESCRIPTION

The DLM-920 is a digital microprocessor control device specifically

designed to protect gas compressors from damage due to loss of

lubrication . Lubrication to the compressor flows through a divider

block lubrication system forcing an internal piston to cycle back and

forth. With the Proximity Switch, ordered separately, mounted to

one of the divider blocks, this back and forth movement results in an

ON/OFF state which the DLM-920 continuously analyzes. If no

movement is detected, the DLM-920 will activate the alarm delay

which is easily adjustable from 20 sec's. to 4 mins. 30 sec's. When

the alarm delay expires, "shutdown" of the compressor will occur preventing any damage.

OPERATION

The DLM-920 alarm time can be viewed by pressing and

holding the "Reset" button which will reset the "Cycle

Indicator" to zero and flash the alarm time at one second

intervals. To view changing the alarm time, simply hold the

"Reset" button down and turn the potentiometer. Adjustment

of the alarm time is possible without holding the "Reset"

button down so that the counter does not reset to zero. The

alarm time is not affected by temperature change. The DLM-

920 is a bipolar device. It is not necessary to determine the

polarity of the wires coming from the annunciator, PLC, or

other types of shutdown controllers because the closed loop

and open loop alarm circuits are bipolar.