< Back to Lubrication Monitors

Digital Lubrication Monitor Model DLM-812 - Part# 000783

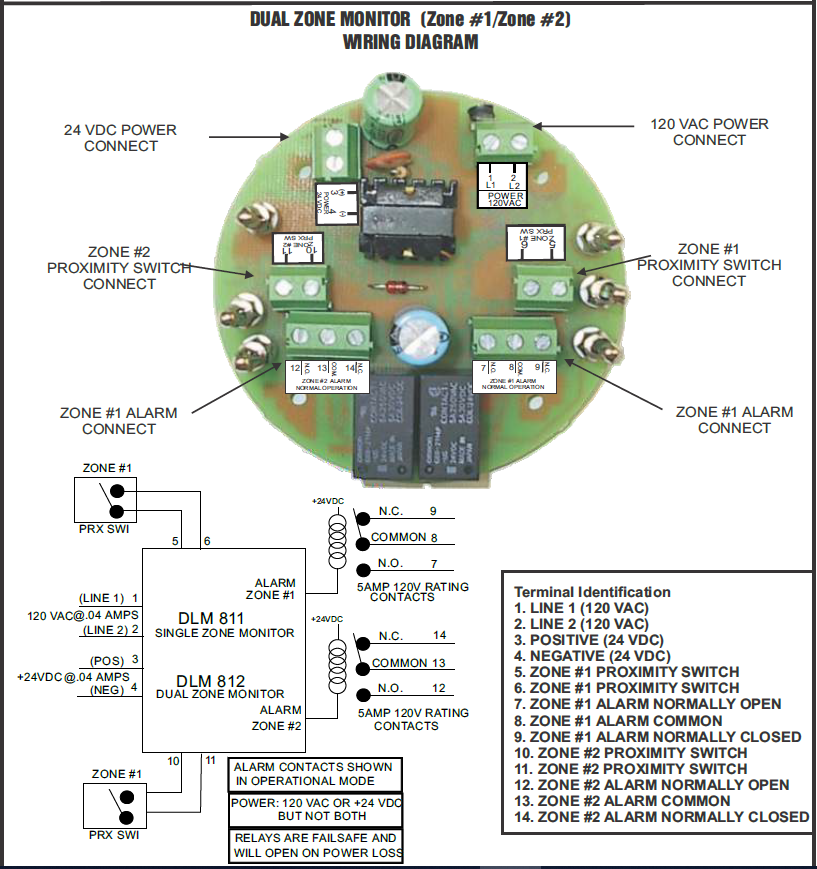

DUAL ZONE MONITOR (Zone #1/Zone #2)

MONITORS AND RECORDS OPERATION OF DIVIDER BLOCK LUBRICATION SYSTEMS

DISPLAY FUNCTIONS: Pints/Day ZONE#1 and ZONE #2

Z1 XXX.X P/D Pints/Day Zone #1

Z2 XXX.X P/D Pints/Day Zone #2

Cycle time ZONE#1

Z1 XXX.X SEC Cycle time in seconds

PREV. XXX.X Previous Cycle time for Zone#1

Cycle time ZONE #2

Z2 XXX.X SEC Cycle time in seconds

PREV. XXX.X Previous Cycle time for Zone#2

Total strokes ZONE#1 and ZONE #2

Z1 XXXXXX STK Total Strokes Zone#1

Z2 XXXXXX STK Total Strokes Zone #2

Total run time in hours

000000.000

SPECIFICATIONS

Enclosure.............................Compliant with Class I Division I Groups B, C, D

Power....................................20VAC or 24VDC@.040 amps

Alarm Switch........................Form C Contact 120 VAC @ 5 amps N.O. COM. N.C.

Alarm Time............................Programmable - 3 sec to 250 seconds

Temperature Range...............0o to +150o F (-32o to +70o C)

Warranty.................................1 Year

Display...................................Cycle Time(Sec), Flow Rate(Pints/Day), Total Strokes,

Alarm Status, Total System Run Time(Hours)

Memory.................................100 Cycle times Zone #2, 100 Cycle times Zone #1

DESCRIPTION

The DLM-812 is a microprocessor based dual mode

monitor for the display and control of progressive in- line

lubrication systems. Proximity switches mounted to the

divider block system for Zone #1 and Zone #2 signals the

DLM812 each cycle. The time between cycles is

displayed on the LCD readout as time into the current

cycle as well as the time for the previous cycle. Each 10

seconds the display changes to show the flow rate in

pints/day, cycle time, total strokes, and system run time

for both Zone #1 and Zone #2. If the time between

cycles exceeds the programed alarm time an alarm

signal is activated. The last I00 cycle times for the

Zone #1 and Zone #2 lubrication systems are stored in

permanent memory and can be read out via local control

of program buttons.

(Note: Program instructions shown for Zone 1, instructions are the same for zone 2.)

PROGRAMMING FUNCTIONS

Press PRG. and hold PRG. use INC. or DEC. buttons to change

functions. Pressing Exit button will return to normal operation.

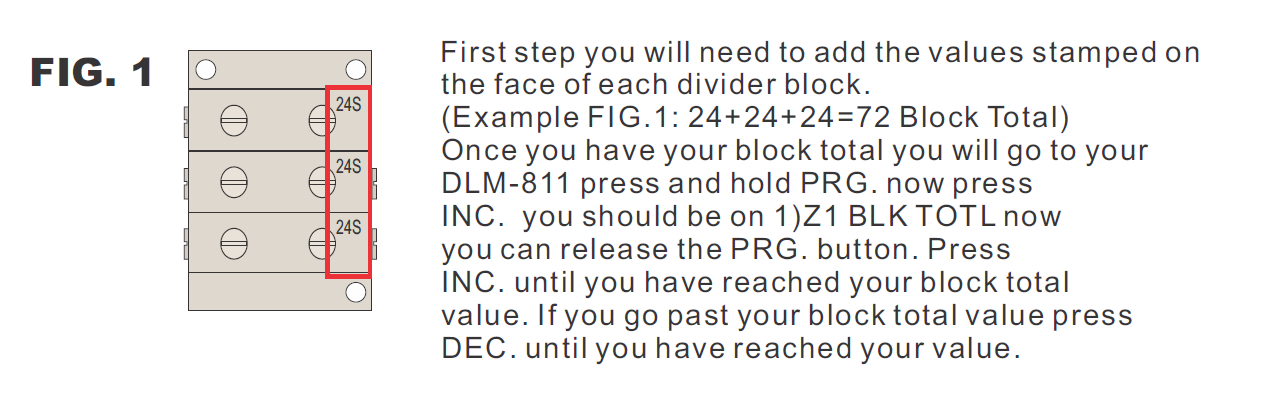

1)Z1 BLK TOTL= Block Total - Programmable between 18-144. Use

INC or DEC Button to set block Total for Zone #1.

3)Z1 ALR SEC= Alarm Time - Programmable between 3-250 seconds.

Use INC or DEC Button to set block Total for Zone #1.

5)MEMORY Z1= Cycle Time Memory - Use INC or DEC Button to view

last 100 cycle times for Zone #1.

NOTE: Memory is permanent, will not be lost in case of power failure.

7)RESET?_= System Reset - Press the INC or DEC Buttons at the same

time to reset total strokes and hours.

DISPLAY: Automatically scrolls between Pints/Day, Cycle Time, Total Strokes,

System Run Time.

Pressing (INC.) W ill lock display at the present function.

Pressing the (EXIT) will release the scroll lock and retur n to automatic.

Four(4) panel mounted buttons are used to change the setup parameters.

Program menu items are accessed by pressing the PRG button.

Pressing the PRG and either INC. or EXT at the same time will access the other menu items.

The INC. and EXT buttons will change a menu item slowly at first then rapidly if held down.

The exit button will return to the display mode if pressed at any time.

< Back to Lubrication Monitors